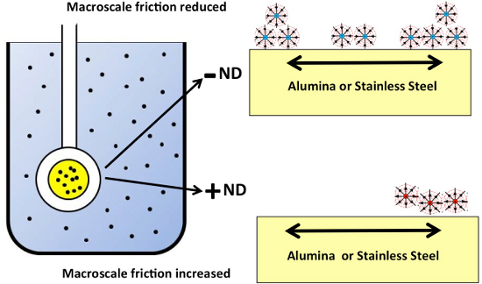

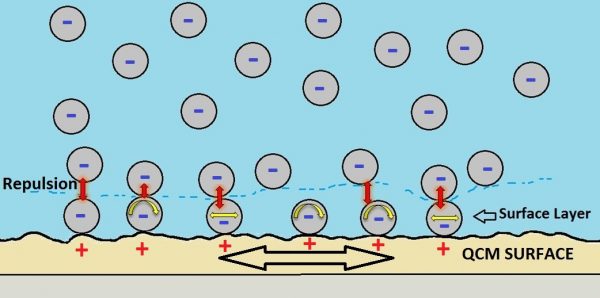

Effective control of friction, wear and adhesion has a vast range of applications, including energy efficiency, national security, manufacturing, pharmaceuticals and the environment. Existing lubrication technologies were developed in an era that focused on wear elimination over energy losses from friction, with less consideration of environmental consequences. There is a pressing need for revolutionary new materials that would reduce friction and wear, and also eliminate the harsh environmental impacts of current materials. This DMREF project seeks to develop and test a new approach for rational design of materialliquid-nanoparticulate systems to achieve superior tribological performance. Theory, simulation, statistics, synthesis and characterization will be iteratively combined to develop design rules for controlling friction, adhesion and wear at material-liquid-nanoparticulate interfaces.

This project is generously supported by the National Science Foundation.